Thicker coatings

Researchers at Bristol have overturned a 60-year old equation and discovered a new way of varying the thickness of fluid film coatings.

Eureka! Jump out of the bath fast enough and a fair proportion of the water will do the same with you.

While that's to be expected of a complex shape like the human form, even a flat vertical plate raised from a bath of fluid will be accompanied by some of the fluid in the form of a thin film, stretched over the surface of the plate. This property is the basis of many industrial and manufacturing processes for dip-coating, for example, applying UV filters to vehicle windscreens.

For any given viscosity of fluid, the thickness of the film deposited on the plate is largely governed by the speed at which the plate is withdrawn from the bath. Generally speaking, the faster the plate travels, the thicker the film. The equation which expresses this relationship was formulated by Landau and Levich in 1942:

![]()

Or, put into words, the thickness of the film is proportional to the two-thirds power of the velocity with which the plate is withdrawn from the fluid bath.

However, through a series of theoretical calculations, Prof Jens Eggers and Dr Jacco Snoeijer have found conditions under which the thickness of the film is proportional to the half power of velocity and which can be used to produce a thicker film:

![]()

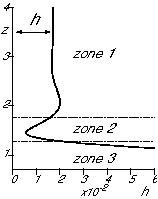

Their calculations predict that the transition (where the liquid from the bath is stretched over the receding plate) occurs due to the appearance of a solitary wave.

The deposition of the film can be observed in three zones where different forces are dominant.

In zone 1 gravity and viscosity are the dominant forces; in zone 2 viscosity and surface tension; and in zone 3 gravity and surface tension.

In zone 1 gravity and viscosity are the dominant forces; in zone 2 viscosity and surface tension; and in zone 3 gravity and surface tension.

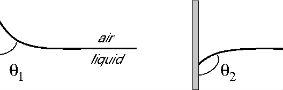

Prof Eggers and Dr Snoeijer discovered that the thickness of the film is dependent on the hydrophobic or hydrophilic properties of the fluid and plate surface.

When the plate is at rest, the meniscus of a conventional hydrophilic liquid/plate combination creates an angle θ1 whereas that of a hydrophobic combination creates the angle θ2.

When the plate is withdrawn from the fluid bath, the value of this angle affects the formation of the capillary ridge and hence the thickness of the film deposited under certain velocities of withdrawal.

This means that within certain limits of velocity, the thickness of the film can be increased by first treating the surface with a substance which makes the desired coating act in a hydrophobic way.

This means that within certain limits of velocity, the thickness of the film can be increased by first treating the surface with a substance which makes the desired coating act in a hydrophobic way.