Cleanroom

Open to all researchers at the university and accessible for external organisations as well, our cleanroom enables wafer-scale micro and nano fabrication. It comprises several class-1000-rated rooms and houses process tools for lithography, dry etch, deposition, chemical processing, post processing and characterisation. These tools are used for rapid prototyping of a range of devices, including photonic structures, microfluidics, micro-lenses, integrated circuits and MEMS. Equipment and specifications listed below.

Lithography

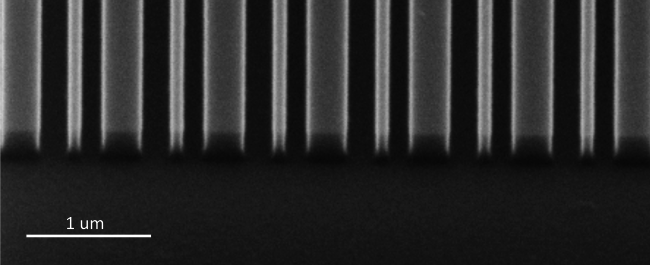

Raith Voyager EBL system

- High performance electron beam lithography tool

- Greater than 1cm²/hr writing speed (at 50 % pattern density)

- 8nm linewidth in HSQ resist

- 30nm pitch grating with 10nm linewidth

- Stitching accuracy <20nm

- Fixed Beam Moving Stage (FBMS) and Modulated Beam Moving Stage (MBMS) patterning modes available (stitching-error-free)

- Linear grating coupler fabricated on SOI wafer

Karl Suss MJB3 Mask Aligner

- 3" maximum wafer size

- UV 400 optics

- Standard processes available using S1800 series, LOR, AZ resists

- Sub-micron resolution achievable in vacuum contact mode

MIDAS MDA-400M-6 Mask Aligner

- Up to 6" wafer size

- Sub-micron resolution in vacuum contact mode

- Backside alignment using through-wafer IR illumination

- Beam uniformity of 3% across 4" wafer

Zeiss EVO SEM and EBL system

- 30 kV accelerating voltage

- Raith ELPHY plus patterning system

- 50nm linewidth resolution

- Imaging with tilt and rotation

Dry etch

RIE - Silicon dioxide and silicon nitride etch

- JLS Designs Plasmapod Plus and Plasmatherm RIE 550-570

- Available for etching SiO2 and Si3N4

- Primarily these system are used to produce hard masks for further wet and dry etching steps

- Other materials have also been etched in the Plasmatherm system, most recently polyimide

- Gases available are CF4, CHF3, Ar, O2

RIE - Silicon etch and niobium nitride etch

- JLS Designs Plasmapod RIE

- Used for etching silicon and superconducting thin films such as niobium nitride

- Available gases are SF6, CHF3, Ar and O2

- A further two gas lines are currently spare

ICP-RIE - Oxford Instruments system 100 ICP 180

- Configured for III-V, II-VI etching

- 4" wafer holder

- Up to 8 process gases available that are suitable for etching a wide range of materials, including silicon and LiNbO3

- Standard processes available for high quality InP etching

ICP-RIE - Oxford Instruments System 100 Cobra

- Configured for high quality Si etching

- SF6-based etch processes

- Etch recipes for

- RIE, ICP-RIE

- Bosch

- Cryo

- 4" wafer holder, can be configured for up to 8"

- Laser end-point detection

Plasma asher - Diener Zepto

- O2 and Ar plasma asher

- Surface functionalisation and sample cleaning

- 105mm diameter chamber

Deposition

Sputter Coater - Moorfield Minilab

- Three targets, 2" diameter - Au, NiCr, Ti, Pd, Pt available and other materials by request

- Rotational sample holder

- Confocal or parallel sputter head orientation

- Better than +/- 5% uniformity across 4" wafer (confocal deposition)

Thermal Evaporator - Edwards E306

- Metal deposition - Au, Ni, Ag, Al, Cr, other metals by request

- Thin films, usually < 300 nm

- Base pressure typically 1.10-6 mbar

PECVD - Oxford Instruments System 100

- a-Si, SiO2 and Si3N4 deposition

- Loadlocked system

- Ammonia-free Si3N4 recipes available

E-beam evaporator - Moorfield Minilab

- Metal deposition: Au, Ti, Al, others by request

- Dielectric material deposition: Al2O3, SiO2

- Six-pocket e-beam gun with 7 cc volume

- Integrated into sputter coater system

Chemical processing

Wet benches

- Acid/base processing

- HF processing

Fume cupboards

- Solvent cleaning

- Spin station (photoresists)

- Spin station (coating system for SU-8 and spin coater for EBL resists)

Standard etch processes

- Transene TFA Au etch

- Transene TFG Ni etch

-

Transene TFN NiCr etch

-

Aqua regia

-

Piranha

-

HF/BOE

Post processing

Cammax Precima EDB80 Die Bonder

- Eutectic die bonder

- Precision placement

- Vacuum pick and place

Loadpoint Microace Series 3 Wafer Dicer

- 4" wafer compatible

- Variety of cutting modes

- Single and multi pass

- Programmable rotation with 0.005° resolution

- Square, circular, hexagonal substrates, up to 8 mm thick

- Servo-driven y-axis with 2 μm resolution

- Feed-rate from 0.1 mm/sec upwards

- Spindle speed from 3000-40000 rpm

Suss Auto Scriber

- Precision diamond scribing

- Optical alignment

- 3" wafer vacuum chuck

K&S 4524 Wire Bonder

- Gold ball bonding

- 25um diameter wire

- Fine pitch capillaries available

TPT HB16 Wire Bonder

- Gold ball and wedge bonding (25um diameter as standard)

-

Aluminium wedge bonding (33um diameter as standard)

-

17-50um diameter wire bonding possible

-

Fine pitch capillaries available

-

Loop control

-

Manual, semiautomatic, automatic bonding

Characterisation

Zeiss EVO SEM

- SEM used for surface characterisation and imaging

- 5-30kV accelerating voltage

- Primarily a patterning tool, but available for some imaging purposes

- Variable pressure mode available

Agilent Atomic Force Microscope

- High precision, scientific-grade microscope, providing atomic-scale resolution

- Applications in material science, polymers and general surface characterisation

- Contact and Intermittent contact AFM modes available

Dektak Surface Profiler

- Stylus with 2 μm diameter tip

- 3D profilometer

- Step height repeatability of 4 Å possible

- Vertical size limit of 1 mm

- 6" wafer compatible

J A Woollam RC2 Spectroscopic Ellipsometer

-

High quality measurement of thin film and bulk characteristics including

- Optical dispersion (complex refractive index, dielectric permittivity)

- Film thickness

- Multi-layer characterisation

- Films may be isotropic or anisotropic, homogenous or graded

- Wide wavelength range: 210-2500 nm

- Variable angle: 45-90 degrees

Filmetrics Profilm3D Optical Profilometer

- Interferomtric white light profilometer

- Measures surface profiles with vertical feature resolution down to 0.001 µm by using white light interferometry (WLI)

- Automated XY stage

- Two objective lenses

- 20x : field of view = 1.0 x 0.85 mm (spatial sampling = 0.44 um)

- 100x : field of view = 0.2 x 0.17 mm (spatial sampling = 0.088 um)

Filmetrics White-Light Reflectometer

- Quick and easy thin film thickness measurement

- Wafers up to 6"

Inspection microscopes

- Variety of inspection microscopes available

- Polyvar Polymet microscope fitted with objectives ranging from x2.5 to x150 calibrated to permit length measurements

- Leica viewers and inspection microscopes also available

Cleanroom requests

To enquire about using the cleanroom, please email Cleanroom Manager Dr Andrew Murray or call him via +44 (0)117 455 7741.

Proposal Form

Project Proposal Form (Office document, 31kB) and submit this to the Cleanroom staff.

Enquiries

Dr Andrew Murray

Dr Pisu Jiang

Senior Cleanroom Process Engineer

0117 455 4243

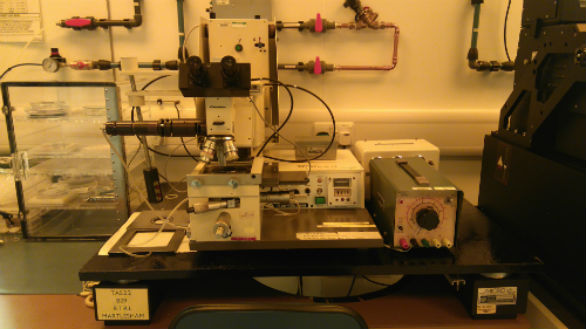

Virtual tour

Virtual tour

Explore our facilities and equipment with our Cleanroom virtual tour

Health and safety

Health and safety

Read our Cleanroom user guide (PDF, 95kB) about how to safely use the cleanroom and its facilities.

.png)