Multi-physics Modelling of Electromechanical Systems

In the EEMG, we have developed numerous tools and techniques for the coupled multi-physics analysis of actuators, electrical machines and wound passive components. The modelling techniques employed are tailored to a particular problem in order to achieve computationally efficient design methodologies.

The desire for electrical machines and devices to meet evermore demanding specifications in terms of power-density, energy-efficiency, and short-duty operation, requires electromagnetic, thermal, and other relevant physical phenomena to be accounted for simultaneously at the design stage through the use of coupled multi-physics design methodologies employing combinations of analytical lumped parameter and numerical modelling techniques along with appropriate optimization routines.

A major limiting factor on the energy conversion capability of such electrical machines and devices is the ability to dissipate internally generated heat and, in turn, the temperature rating of the electrical insulation system and permanent magnets (PMs), if present.

A major limiting factor on the energy conversion capability of such electrical machines and devices is the ability to dissipate internally generated heat and, in turn, the temperature rating of the electrical insulation system and permanent magnets (PMs), if present.

Therefore, in the design of high-performance machines and devices, the electromagnetic and thermal phenomena should be accounted for, at a minimum, to allow a greater exploitation of materials and yield more compact and lighter designs.

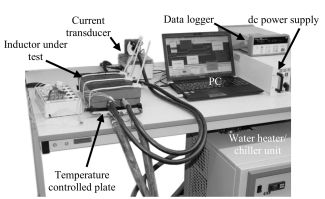

Derivation and Scaling of AC Copper Loss in Thermal Modeling of Electrical Machines

Accurate prediction of temperature-dependent ac winding loss effects is crucial in the design of electrical machinery. Average ac winding loss as a function of operating frequency is commonly characterized by the ratio of the equivalent ac and dc resistances (Rac/Rdc). However, as the ac and dc components of the winding loss scale differently with temperature, a single value of Rac/Rdc derived for one temperature can be inadequate when used in thermal modeling. Methods of deriving the Rac/Rdc ratio, together with scaling techniques of the ac winding loss accounting for thermal effects, are investigated [1]. As an alternative to computationally intensive 3-D finite-element analysis, an experimental approach based on tests on full-scale stator assemblies has been proposed.

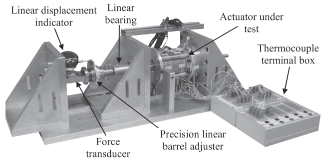

A Multiphysics Design Methodology Applied to a High-Force-Density Short-Duty Linear Actuator

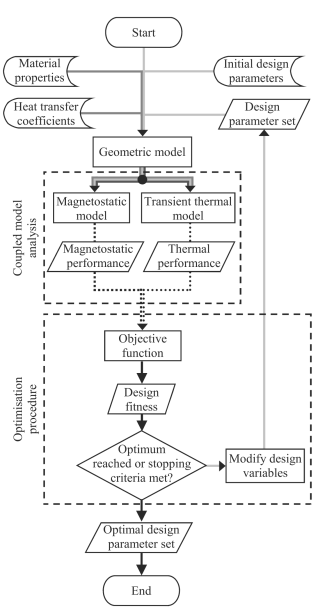

A coupled electromagnetic and thermal design methodology is used to address the problem of balancing accuracy against computation time.

The proposed method employs a two-dimensional electromagnetic finite-element (FE) model coupled with a detailed thermal equivalent circuit (TEC) model which is automatically constructed and parameterized using geometric and material data [2]. A numerical method of estimating the equivalent thermal properties of the winding amalgam is used along with published empirically derived convection and radiation heat transfer correlations. The relatively high number of network nodes and more accurate thermal material properties minimizes model calibration and allows improved temperature prediction, including winding hot spots, while maintaining a low computational cost for both steady-state and transient analyses. A comparison between experimental and theoretical actuator performance shows that the design methodology provides good accuracy electromagnetic and transient thermal performance predictions without the need for direct model calibration and can yield an optimized design within an acceptable time frame.

The proposed method employs a two-dimensional electromagnetic finite-element (FE) model coupled with a detailed thermal equivalent circuit (TEC) model which is automatically constructed and parameterized using geometric and material data [2]. A numerical method of estimating the equivalent thermal properties of the winding amalgam is used along with published empirically derived convection and radiation heat transfer correlations. The relatively high number of network nodes and more accurate thermal material properties minimizes model calibration and allows improved temperature prediction, including winding hot spots, while maintaining a low computational cost for both steady-state and transient analyses. A comparison between experimental and theoretical actuator performance shows that the design methodology provides good accuracy electromagnetic and transient thermal performance predictions without the need for direct model calibration and can yield an optimized design within an acceptable time frame.

An Accurate Mesh-Based Equivalent Circuit Approach to Thermal Modeling

A method of automatically constructing and parameterizing accurate lumped parameter thermal equivalent circuits (TECs) with nodes arranged in a regular mesh pattern has been developed [3].

The approach exhibits a number of advantages over conventional lumped parameter TECs including superior thermal field resolution, reduced model construction and setup times and more accurate identification of hot-spot temperatures and their location. The method serves as a desirable compromise between the fine detail and high computational cost of a full finite element analysis and the coarse detail and short solution times afforded by lumped parameter TECs.

The approach exhibits a number of advantages over conventional lumped parameter TECs including superior thermal field resolution, reduced model construction and setup times and more accurate identification of hot-spot temperatures and their location. The method serves as a desirable compromise between the fine detail and high computational cost of a full finite element analysis and the coarse detail and short solution times afforded by lumped parameter TECs.

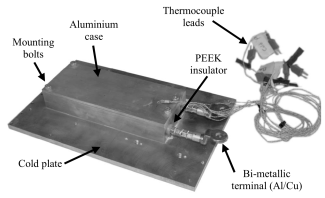

Estimation of Equivalent Thermal Parameters of Impregnated Electrical Windings

It is common practice to represent a composite electrical winding as an equivalent lumped anisotropic material as this greatly simplifies a thermal model and reduces computation times. Existing techniques for estimating the bulk thermal properties of such composite materials use either analytical, numerical, or experimental approaches; however, these methods exhibit a number of drawbacks and limitations regarding their applicability.

A numerical thermal conductivity and analytical specific heat capacity estimation technique has been proposed [4], [5], [6]. The method is validated experimentally against three winding samples with differing configuration. A procedure has been developed which enables bulk thermal properties to be estimated with a minimal need for experimental measurement, thereby accelerating the thermal modeling process. Experimental thermal transients obtained by dc test of the coils show close agreement with a lumped-parameter thermal model utilizing estimated material data.

A numerical thermal conductivity and analytical specific heat capacity estimation technique has been proposed [4], [5], [6]. The method is validated experimentally against three winding samples with differing configuration. A procedure has been developed which enables bulk thermal properties to be estimated with a minimal need for experimental measurement, thereby accelerating the thermal modeling process. Experimental thermal transients obtained by dc test of the coils show close agreement with a lumped-parameter thermal model utilizing estimated material data.

References

[1] R. Wrobel, D. E. Salt, A. Griffo, N. Simpson and P. H. Mellor, "Derivation and Scaling of AC Copper Loss in Thermal Modeling of Electrical Machines," in IEEE Transactions on Industrial Electronics, vol. 61, no. 8, pp. 4412-4420, Aug. 2014.

[2] N. Simpson, R. Wrobel and P. H. Mellor, "A Multiphysics Design Methodology Applied to a High-Force-Density Short-Duty Linear Actuator," in IEEE Transactions on Industry Applications, vol. 52, no. 4, pp. 2919-2929, July-Aug. 2016.

[3] N. Simpson, R. Wrobel and P. H. Mellor, "An Accurate Mesh-Based Equivalent Circuit Approach to Thermal Modeling," in IEEE Transactions on Magnetics, vol. 50, no. 2, pp. 269-272, Feb. 2014.

[4] N. Simpson, R. Wrobel and P. H. Mellor, "Estimation of Equivalent Thermal Parameters of Impregnated Electrical Windings," in IEEE Transactions on Industry Applications, vol. 49, no. 6, pp. 2505-2515, Nov.-Dec. 2013.

[5] S. Ayat, R. Wrobel, J. Goss, D. Drury, “Estimation of Equivalent Thermal Conductivity for Impregnated Electrical Windings Formed from Profiled Rectangular Conductors”, 8th IET International Conference on Power Electronics, Machines and Drives (PEMD), Glasgow, April 2016.

[6] R. Wrobel, P. H. Mellor, “A General Cuboidal Element for Three-Dimensional Thermal Modelling,” IEEE Transactions on Magnetics, vol. 46, no. 8, pp. 3197-3200, August 2010.