Cleanroom

Open to all researchers at the university and accessible for external organisations as well, our cleanroom enables wafer-scale micro and nano fabrication. It comprises several class-1000-rated rooms and houses process tools for lithography, dry etch, deposition, chemical processing, post processing and characterisation. These tools are used for rapid prototyping of a range of devices, including photonic structures, microfluidics, micro-lenses, integrated circuits and MEMS. Equipment and specifications listed below.

Lithography

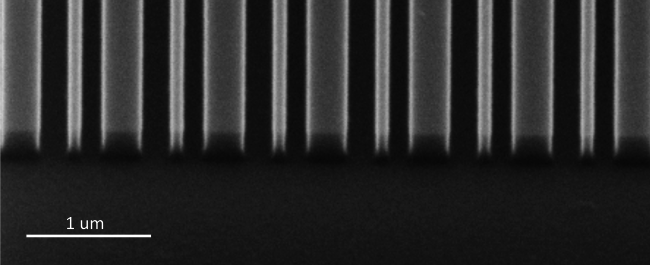

- High performance electron beam lithography tool

- Greater than 1cm²/hr writing speed (at 50 % pattern density)

- 8nm linewidth in HSQ resist

- 30nm pitch grating with 10nm linewidth

- Stitching accuracy <20nm

- Fixed Beam Moving Stage (FBMS) and Modulated Beam Moving Stage (MBMS) patterning modes available (stitching-error-free)

- Linear grating coupler fabricated on SOI wafer

- 3" maximum wafer size

- UV 400 optics

- Standard processes available using S1800 series, LOR, AZ resists

- Sub-micron resolution achievable in vacuum contact mode

- Up to 6" wafer size

- Sub-micron resolution in vacuum contact mode

- Backside alignment using through-wafer IR illumination

- Beam uniformity of 3% across 4" wafer

- 30 kV accelerating voltage

- Raith ELPHY plus patterning system

- 50nm linewidth resolution

- Imaging with tilt and rotation

Dry etch

- JLS Designs Plasmapod Plus and Plasmatherm RIE 550-570

- Available for etching SiO2 and Si3N4

- Primarily these system are used to produce hard masks for further wet and dry etching steps

- Other materials have also been etched in the Plasmatherm system, most recently polyimide

- Gases available are CF4, CHF3, Ar, O2

- JLS Designs Plasmapod RIE

- Used for etching silicon and superconducting thin films such as niobium nitride

- Available gases are SF6, CHF3, Ar and O2

- A further two gas lines are currently spare

- Configured for III-V, II-VI etching

- 4" wafer holder

- Up to 8 process gases available that are suitable for etching a wide range of materials, including silicon and LiNbO3

- Standard processes available for high quality InP etching

- Configured for high quality Si etching

- SF6-based etch processes

- Etch recipes for

- RIE, ICP-RIE

- Bosch

- Cryo

- 4" wafer holder, can be configured for up to 8"

- Laser end-point detection

- O2 and Ar plasma asher

- Surface functionalisation and sample cleaning

- 105mm diameter chamber

Deposition

- Three targets, 2" diameter - Au, NiCr, Ti, Pd, Pt available and other materials by request

- Rotational sample holder

- Confocal or parallel sputter head orientation

- Better than +/- 5% uniformity across 4" wafer (confocal deposition)

- Metal deposition - Au, Ni, Ag, Al, Cr, other metals by request

- Thin films, usually < 300 nm

- Base pressure typically 1.10-6 mbar

- a-Si, SiO2 and Si3N4 deposition

- Loadlocked system

- Ammonia-free Si3N4 recipes available

- Metal deposition: Au, Ti, Al, others by request

- Dielectric material deposition: Al2O3, SiO2

- Six-pocket e-beam gun with 7 cc volume

- Integrated into sputter coater system

Chemical processing

- Acid/base processing

- HF processing

- Solvent cleaning

- Spin station (photoresists)

- Spin station (coating system for SU-8 and spin coater for EBL resists)

- Transene TFA Au etch

- Transene TFG Ni etch

-

Transene TFN NiCr etch

-

Aqua regia

-

Piranha

-

HF/BOE

Post processing

- Eutectic die bonder

- Precision placement

- Vacuum pick and place

- 4" wafer compatible

- Variety of cutting modes

- Single and multi pass

- Programmable rotation with 0.005° resolution

- Square, circular, hexagonal substrates, up to 8 mm thick

- Servo-driven y-axis with 2 μm resolution

- Feed-rate from 0.1 mm/sec upwards

- Spindle speed from 3000-40000 rpm

- Precision diamond scribing

- Optical alignment

- 3" wafer vacuum chuck

- Gold ball bonding

- 25um diameter wire

- Fine pitch capillaries available

- Gold ball and wedge bonding (25um diameter as standard)

-

Aluminium wedge bonding (33um diameter as standard)

-

17-50um diameter wire bonding possible

-

Fine pitch capillaries available

-

Loop control

-

Manual, semiautomatic, automatic bonding

Characterisation

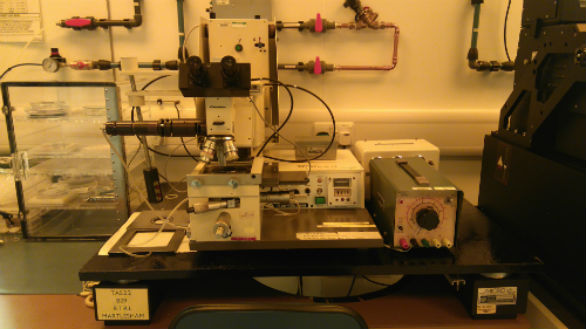

- SEM used for surface characterisation and imaging

- 5-30kV accelerating voltage

- Primarily a patterning tool, but available for some imaging purposes

- Variable pressure mode available

- High precision, scientific-grade microscope, providing atomic-scale resolution

- Applications in material science, polymers and general surface characterisation

- Contact and Intermittent contact AFM modes available

- Stylus with 2 μm diameter tip

- 3D profilometer

- Step height repeatability of 4 Å possible

- Vertical size limit of 1 mm

- 6" wafer compatible

-

High quality measurement of thin film and bulk characteristics including

- Optical dispersion (complex refractive index, dielectric permittivity)

- Film thickness

- Multi-layer characterisation

- Films may be isotropic or anisotropic, homogenous or graded

- Wide wavelength range: 210-2500 nm

- Variable angle: 45-90 degrees

- Interferomtric white light profilometer

- Measures surface profiles with vertical feature resolution down to 0.001 µm by using white light interferometry (WLI)

- Automated XY stage

- Two objective lenses

- 20x : field of view = 1.0 x 0.85 mm (spatial sampling = 0.44 um)

- 100x : field of view = 0.2 x 0.17 mm (spatial sampling = 0.088 um)

- Quick and easy thin film thickness measurement

- Wafers up to 6"

- Variety of inspection microscopes available

- Polyvar Polymet microscope fitted with objectives ranging from x2.5 to x150 calibrated to permit length measurements

- Leica viewers and inspection microscopes also available