Extended projects 2016 cohort

- Weak-links: main group bonds for mechanochemistry, dynamic combinatorial chemistry and covalent adaptable networks

- Granular jamming as a variable stiffness mechanism for morphing aerostructures

- Development of embedded vascular networks in FRPs for active/passive thermal management

- From lamination parameters to manufacturable stacking sequence

- Soft robotic wing structures

- Novel tow termination technology for high-quality AFP production

- Transformers: embedded actuation of folded structures

- New methods for the testing of through-thickness/interlaminar shear stress influence on in-plane fibre tensile strength of CFRP

- Modelling the process induced stress state around particles in the interleaf: A proposed link between stress state and toughness

- Design, manufacturing, and testing of an automated winding machine for WrapToR composite truss structures

- Enhancement of CO2 capture in MIL-101 by amine incorporation

- Designing bend‐twist coupled blades for the segmented ultralight morphing rotor

- Fabrication of pulsed DC plasma-assisted CVD diamond films on metal composites for deep-well drill bits

- A novel framework for multi-disciplinary optimisation of aeroelastically tailored wind turbine blades

- Stiffness tailoring of composite shells via thermal prestress

- Understanding the in-plane behaviour of prepreg tapes: improving the part quality and deposition rate of automated manufacturing

Weak-links: main group bonds for mechanochemistry, dynamic combinatorial chemistry and covalent adaptable networks

Student: Callum Branfoot

Student: Callum Branfoot

Supervisors: Duncan Wass, Ian Bond and Paul Pringle

Main group covalent bonds, including the previously unexplored P–P bond, have been investigated for potential application in the related fields of mechanochemistry, dynamic combinatorial chemistry (DCC) and covalent adaptable networks (CANs). Small-molecule metathesis experiments based on literature studies with disulfide bonds have been carried-out with diphosphines and diselenides to probe bond stability. Polymers containing these mechanically labile units were then designed, prepared and tested to assess the viability of their application as dynamic bonds and/or mechanophores.

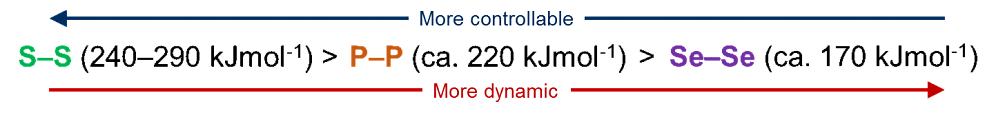

Small-molecule diselenides were prepared and tested under a range of metathesis conditions. The Se–Se bond was observed to be so weak that it readily dissociated without an external stimulus. By contrast, small-molecule biphosphines were subject to similar conditions but exhibited more controllable reactivity: the P–P bond was only observed to react in the presence of chlorine radicals, this provides hope of selectively activating P–P bonds with mechanical force. Moreover, diphosphines were observed to be more reactive than disulfides when compared to analogous literature experiments. The metathesis reactivity is thus inversely proportional to bond strength: Se–Se > P–P > S–S, Figure 1.

Figure 1: The bond strengths of the disulfide, diphosphine and diselenide bonds.

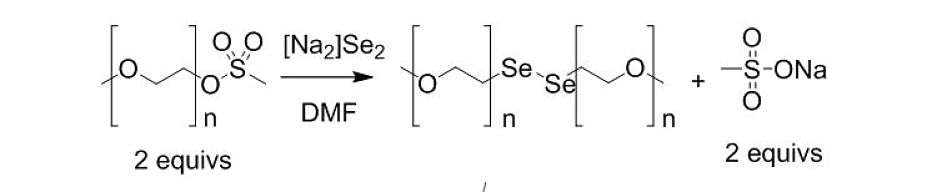

The novel polymer, PEG-Se–Se-PEG was prepared and characterised via GPC, Scheme 1. Although the coupling reaction was successful, ambient laboratory lighting and stirring was sufficient to cleave the Se–Se bond, in agreement with the small-molecule metathesis experiments. This indicates that diselenides are not appropriate candidates for mechanochemistry and only have limited applicability as dynamic bonds: they cleave without an external stimulus. Progress towards developing a P–P-based crosslinker was made although the corresponding polymers have yet to be synthesised.

Scheme 1: The synthesis of a diselenide containing polymer: PEG-Se–Se-PEG.

The results of this study confirm that P–P bonds are appropriate candidates for dynamic covalent chemistry: importantly, these bonds fall between disulfides, which are relatively stable, and diselenides, which are bound so weakly as to preclude their selective activation.

The impact of this technology could be significant, providing a new direction of research within the field of covalent adaptable networks (CANs), which in turn could be exploited for the repair, reshaping or recycling of thermoset polymers.

Granular jamming as a variable stiffness mechanism for morphing aerostructures

Student: David Brigido

Student: David Brigido

Supervisors: Ben Woods and Stephen Burrow

Granular jamming is a physical mechanism present in particulate materials that allows the material to undergo a fast, repeatable state change, from a liquid-like state to a solid-like state and vice versa under the action of a controllable external pressure field, which locks the particles together. If the external pressure field is continuously variable, then granular jamming is also able to create proportional changes in stiffness, thereby creating a material with variable stiffness. The bulk behaviour of the loose material, which is usually built of grains, enclosed inside an impermeable and elastic membrane, is controlled by vacuum. Jammed systems can be used to create structural elements which are required to switch stiffness and change shape, for example soft robots and morphing structures. The aim of this work is to develop a novel concept of morphing wing structure using granular jamming, with the objective to adjust stiffness and control shape for different flight conditions. Further objectives are to reduce noise and drag due to the discontinuities among the control surface and the wing. For a better understanding of the flexural behaviour of the jammed systems, four-point bending tests were conducted to obtain the flexural rigidity and bending stiffness of different grains. Finally, the variable stiffness of the novel morphing concept was analysed in experimental bending tests and was compared with finite element analysis.

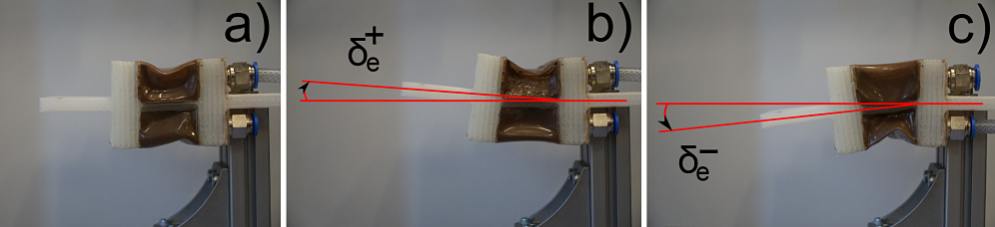

Morphing cell actuation and control for spine deflection. Image a: No spine deflection. Image b: Positive deflections on spine (upper cell contraction and lower cell expansion). Image c: Negative deflections on spine (lower cell contraction and upper cell expansion)

Development of embedded vascular networks in FRPs for active/passive thermal management

Student: Jim Cole

Student: Jim Cole

Supervisors: Ian Bond, Andrew Lawrie and Adam Bishop (Rolls-Royce)

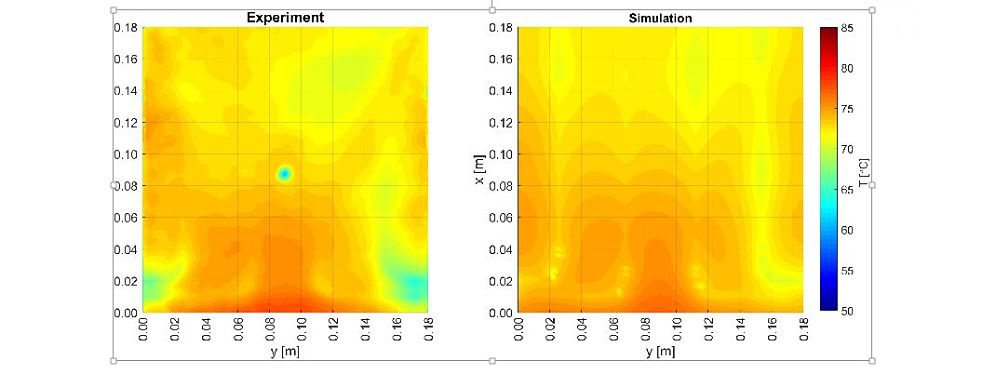

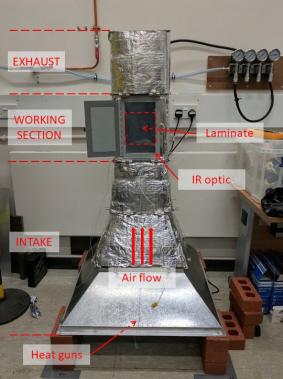

Fibre reinforced polymer composites are currently limited in high temperature applications by the glass transition temperature of the polymer matrix. To address this, a network of narrow conduits, or vascules, was formed within in a carbon fibre/epoxy laminate. Air was forced through the network to provide an active cooling capability. A low speed, high temperature wind tunnel was constructed (see Figure 1), and the laminate surface temperature was monitored to quantify the cooling capacity of the system at flow rates from 1.0 l min-1 to 10.0 l min-1. Reductions from ambient of up to 5.0°C were observed in the peak and average temperatures, and uniformity was high. These results were compared with predictions from a finite difference numerical model, with good agreement (see Figure 2). This confirms the feasibility of the technology, with future work to focus on the structural penalties, network optimisation and manufacturing processes.

Fibre reinforced polymer composites are currently limited in high temperature applications by the glass transition temperature of the polymer matrix. To address this, a network of narrow conduits, or vascules, was formed within in a carbon fibre/epoxy laminate. Air was forced through the network to provide an active cooling capability. A low speed, high temperature wind tunnel was constructed (see Figure 1), and the laminate surface temperature was monitored to quantify the cooling capacity of the system at flow rates from 1.0 l min-1 to 10.0 l min-1. Reductions from ambient of up to 5.0°C were observed in the peak and average temperatures, and uniformity was high. These results were compared with predictions from a finite difference numerical model, with good agreement (see Figure 2). This confirms the feasibility of the technology, with future work to focus on the structural penalties, network optimisation and manufacturing processes.

Figure 1 (right): Thermal wind tunnel used for testing of specimens in high temperature airflow.

Figure 2: Comparison of experimental (left) and numerical simulation (right) results for a given coolant flow rate.

From lamination parameters to manufacturable stacking sequence

Student: Noémie Fedon

Student: Noémie Fedon

Supervisors: Alberto Pirrera, Terence Macquart and Paul Weaver

For laminates made of same laminae, stacking sequence optimisation is a combinatorial problem characterised by a number of variables proportional to the laminate thickness and by design and manufacturing guidelines which restricts the design space in a mostly non-linear fashion. The major drawback of the meta-heuristic optimisers currently used to solve this problem is their decreased performance from medium to high numbers of plies (>40): an increase in the number of plies leads to severe deterioration of the quality of the results or to exponentially increasing computation time. However, there is a rising industrial demand for thicker laminate structures and thus for appropriate design tools.

The stiffness properties of monolithic composite laminates can be expressed with lamination parameters. In doing so, the traditional structural design variables of a stacking sequence (thickness and orientation of each lamina) are replaced by a maximum of 12 lamination parameters. The optimisation is then divided into two steps. First, lamination parameters are used as design variables and their optimal values become the objectives of the second step and the stacking sequences are retrieved. This last step needs improvement as it suffers from the slow convergence of statistic meta-heuristic optimisers such as genetic algorithms.

During the XP, LAYLA, a deterministic optimiser that can retrieve manufacturable stacking sequences from lamination parameters has been developed. It is based on a novel group-by-group approach: ply orientations are successively determined by subsets of plies. LAYLA exhibits low computation time even for laminates with a high ply count (around 10 s). The optimiser also fulfils its expectation in terms of the quality of the results in comparison with the open-source genetic algorithm Opti-BLESS.

Soft robotic wing structures

Student: Calum Gillespie

Student: Calum Gillespie

Supervisors: Jonathan Rossiter, Michael Dicker and Ben Woods

Unmanned Aerial Vehicles (UAVs) have a seen a steady increase in use in both Military and Civil applications. In light of a recent call to investigate the dangers to human health caused by increased use of UAVs a proposed solution could be to use soft structures in the design of these vehicles. This research looks to nature for inspiration for a wing structure with a highly adaptive flight envelope that incorporates the design solutions of soft robotics and the adaptive geometry of morphing aircraft. The membrane wings of the Pterodactyl provide the basis for a soft robotic wing design utilising soft structural components and pneumatic actuators. Numerical modelling was used to determine the parameter limitations of a soft robotic wing resulting in a maximum wing length of 0.6m at a maximum pressurisation of 0.26MPa. 3D printing technology was utilised to design thermoplastic polyurethane bladders and actuators which were pressure tested to determine their feasible use in a wing structure. Additionally, a pneumatic artificial muscle built using more traditional methods was characterised to determine the force versus displacement behaviour to inform and refine the design envelope of the soft robotic wing structure.

Novel tow termination technology for high-quality AFP production

Student: Tharan Gordon

Student: Tharan Gordon

Supervisors: BC Eric Kim, Stephen Hallett and Michael Wisnom

With an ever-increasing drive towards rapid production of more efficient structures, composites manufacture is progressively being automated. The automated fibre placement (AFP) technique is a process that has reached maturity for aerospace components, owing to its ability to rapidly and reliably laminate complex composite structures. However, there remain problems with the introduction of critical defects during the AFP process near to ply drop-off regions. These defects, often referred to as resin pockets, can be critical in nature as they become crack initiation zones upon loading. Conventionally such sites have been accepted as an artefact of manufacture, with much work undertaken to accurately predict and account for their detrimental effect in the design stage. This is at great expense both computationally and in efficiency.

The aim of the proposed research is to study the feasibility of a novel tow termination method. The project will focus on developing a tow scarfing mechanism that automatically tapers the tow ends during the AFP lay-up process, and experimental investigation into the cutting characteristics of representative AFP materials.

Two main advantages are envisioned to follow from this project: (i) composite components formed using the AFP process will have improved performance with respect to delamination onset load (ii) the process will allow for minimisation of the high computational expense of designing and analysing complex tapered laminates.

Transformers: embedded actuation of folded structures

Student: Steven Grey

Student: Steven Grey

Supervisors: Mark Schenk and Fabrizio Scarpa

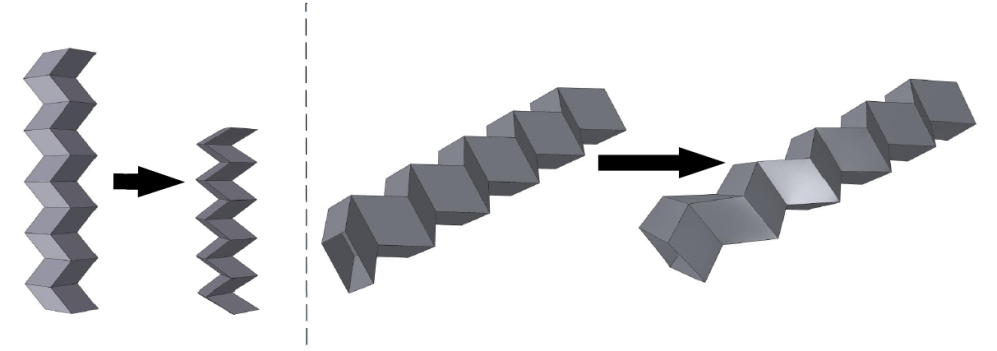

Understanding the decay of actuation in origami would allow the development of a key design tool for engineering deployable or morphing structures based on the folding of materials. Firstly, an understanding of the mechanisms behind the decay is important. The current work uses experimental tests, axially compressing Miura-ori tubes, to provide data on the fold stiffness. These data then feed into numerical and analytical models of a local actuation applied to these structures, which are then experimentally verified. Results show that the stiffness of the folds, and the material between them, affects the profile of the decay. Furthermore, a novel phenomenon has been observed where some unit cells experience a deformation that is opposite to the direction of actuation.

Figure 1: Axial compression (left) and local actuation (right) of Miura-ori tubes.

New methods for the testing of through-thickness/interlaminar shear stress influence on in-plane fibre tensile strength of CFRP

Student: Kilian Grübler

Student: Kilian Grübler

Supervisors: Stephen Hallett, Michael Wisnom and Aleixo Gonzalez (Rolls-Royce)

The application of loads to composite components can lead to complex three-dimensional stress states, especially in the through-thickness direction within the material. Classic analysis of composite structures only covers common stress states in two dimensions, where only the in-plane stresses and properties are considered. Laminated composites are mainly reinforced in-plane which leads to weak through-thickness properties, but there has been much less investigation of through-thickness stress states.

Typical load application and transmission situations which lead to complex three-dimensional stress states and significant through-thickness stresses are thick composite components with high contact loading. In the composite component the most critical stress state region can be found at the edge of the through-thickness loading element. This critical stress state is called edge of bedding stress and can be characterised by high through-thickness and interlaminar shear stresses in combination with longitudinal in-plane tensile stresses.

In previous research, bespoke test methods were developed for testing the material properties of carbon fibre reinforced polymer (CFRP) composites in the presence of high through-thickness compression. It was shown that the interlaminar shear strength of CFRP rises with increased through-thickness compression stress. It was also shown that the longitudinal tensile strength of CFRP decreases significantly with increased through thickness compression stress. However, the interaction and influence of combined through-thickness and interlaminar shear stress on the longitudinal tensile strength was not investigated.

The aim of the six-moth project was the development of a bespoke test method to investigate the influence of combined through-thickness compression and interlaminar shear on the longitudinal fibre tensile strength. With the application of the finite element method (FEM) two bespoke test configurations were designed. With both configurations the influence of a wide range of through-thickness compressive and interlaminar shear stress states on the longitudinal tensile strength of CFRP will be able to be investigated.

This project will be continued as a PhD project. The objectives of the PhD project are to perform such complex stress state tests at different load levels using the bespoke tests developed. Furthermore, a validated modelling tool and failure criteria will be developed.

With such a novel failure criteria composites can be designed more efficiently and reliably. The biggest advantage of a well-developed failure criteria is the increased safety and the mass saving opportunity. These two aspects are of high importance for applications in the aerospace and other industries.

Modelling the process induced stress state around particles in the interleaf: A proposed link between stress state and toughness

Student: Robin Hartley

Student: Robin Hartley

Supervisors: James Kratz, Ian Hamerton, Ivana Partridge, Alex Baidak (Hexcel) and David Tilbrook (Hexcel)

Accurate prediction of the micro-level stress state that arises during the processing of composites is key to understanding their performance and represents an important step towards multiscale modelling in which residual stresses can be used as input parameters when modelling on the macro scale. The performance of particle toughened interleaved systems is particularly poorly understood, with most effort going into identifying failure mechanisms through fractography. In this project an alternative approach is taken, developing a numerical model for the processing of interleaves which can be used in conjunction with a 3D finite element method to show the processing induced stress state that develops around interleaf particles. The analysis demonstrates significant differences in the stress state that is dependent on the both the coefficient of thermal expansion and the modulus of the particle material. It was found that as the modulus of the particle and difference between particle and resin coefficients of thermal expansion increased, the larger the residual stress around and within the particle after processing.

Design, manufacturing, and testing of an automated winding machine for WrapToR composite truss structures

Student: Chris Hunt

Student: Chris Hunt

Supervisors: James Kratz, Ian Hamerton, Ivana Partridge, Alex Baidak (Hexcel) and David Tilbrook (Hexcel)

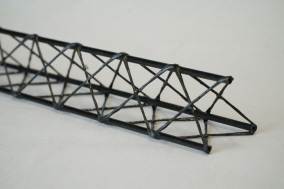

Wrapped tow reinforced (WrapToR) trusses are a family of ultra-efficient composite structures. They are produced by wrapping wetted fibre tow around longitudinal chord members to form a truss geometry. This extended research project looked at the development of a three degree of freedom winding machine for manufacturing of the continuously wound composite truss structures. Automating the winding process allowed faster and more consistent production of wound trusses with better control over process variables than achievable by hand winding. The machine was used for production of test samples to investigate how changing process variables affected the performance of the trusses.

Wrapped tow reinforced (WrapToR) trusses are a family of ultra-efficient composite structures. They are produced by wrapping wetted fibre tow around longitudinal chord members to form a truss geometry. This extended research project looked at the development of a three degree of freedom winding machine for manufacturing of the continuously wound composite truss structures. Automating the winding process allowed faster and more consistent production of wound trusses with better control over process variables than achievable by hand winding. The machine was used for production of test samples to investigate how changing process variables affected the performance of the trusses.

Figure 1 (right): WrapToR truss

Figure 2 (below): Computer generated image of truss winding machine

Enhancement of CO2 capture in MIL-101 by amine incorporation

Student: Konstantina Kanari

Student: Konstantina Kanari

Supervisors: Valeska Ting, Duncan Wass and Phil Patterson (MOF Technologies)

Nowadays rising carbon dioxide levels in the atmosphere are a problem with potentially catastrophic consequences on our environment. Therefore, carbon dioxide capture and sequestration are the goals of urgent ongoing research, both in the academic and industrial sectors. A potential solution is the use of porous materials with enormous surface areas that will selectively capture the carbon dioxide gas in different stages of its cycle, until there is need for its release. However, this requires materials that will be functionable in a wide range of temperature, pressure and combination of gases. Furthermore, the materials should be easy to recover and regenerate, as well as easy to handle. For example, liquid amine solutions that are currently used in industry need the application of high pressure on the gas for its successful flow through the solution. An alternative option are zeolites, that can be hazardous due to their small size.

The aim of this project is the fabrication of a porous lightweight monoliths made of metal-organic frameworks (MOFs) with different pore structures, to be used in the capture and sequestration of carbon dioxide gas. The enormous surface area will enable the selective anchoring of carbon dioxide molecules at different pressures and temperatures, while the monolithic structure will be easy to handle, environmentally friendly and cost-effective.

Designing bend‐twist coupled blades for the segmented ultralight morphing rotor

Student: Anatoly Koptelov

Student: Anatoly Koptelov

Supervisors: Alberto Pirrera, Terence Macquart, Paul Weaver and Todd Griffith (Sandia National Laboratories)

Current trends in the power generation industry show that companies are driven to build larger wind turbines capable of satisfying increasing demands in energy consumption, which leads to the enlargement of main structural components including wind turbine blades.

The current research aims to demonstrate the effectiveness of bend-twist coupling (BTC) in terms of load alleviation by incorporating it into one of the existing designs. For this purpose, Sandia’s SNL100-3 100-metre blade for 13.2 MW downwind wind turbine was picked as a baseline. Based on that model, structural optimisation was performed, the obtained optimised design was compared to a conventional one in terms of root bending moment, tip and average displacements. Results show load reduction by 3.61%.

Fabrication of pulsed DC plasma-assisted CVD diamond films on metal composites for deep-well drill bits

Student: Dominic Palubiski

Student: Dominic Palubiski

Supervisors: Neil Fox and Fabrizio Scarpa

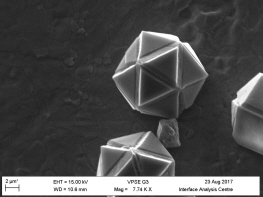

This project investigated the viability of utilizing diamond films grown with a pulsed direct current, plasma assisted, CVD reactor onto tungsten substrates as possible surface coating for deep well drill bit applications. The new instrument should allow for faster deposition rates without sacrificing quality compared to other CVD methods. Growth was done in very low power, high pressure setup (~260 Torr and ~1.75 Kw) and various run times were experimented with to observe not only growth rate but also film formation and long term stability of the plasma.

This project investigated the viability of utilizing diamond films grown with a pulsed direct current, plasma assisted, CVD reactor onto tungsten substrates as possible surface coating for deep well drill bit applications. The new instrument should allow for faster deposition rates without sacrificing quality compared to other CVD methods. Growth was done in very low power, high pressure setup (~260 Torr and ~1.75 Kw) and various run times were experimented with to observe not only growth rate but also film formation and long term stability of the plasma.

SEM data showed growth of both {111} and {100} diamond faces through variations in deposition conditions, as well an impressive 80 μmh-1 growth rate. Full films could be grown in under an hour, which helps to showcase this instruments great potential. Unfortunately overheating of the samples led to a lot of issues with graphitic deposition, reducing the quality of the produced films. On top of this partial coverage meant uneven deposition for most of the produced films, which arose due to the high pressure, low power conditions that were being used.

Overall much success was had with producing diamond coatings. While further work is needed to solve the heating issue as well as the coverage issue, current research is showcasing a very exciting viability to challenge the status quo of diamond fabrication.

Figure 1 (above right): Diamond growth from a short (~20 min) run, showcasing uniform growth but was halted before full film growth was achieved.

A novel framework for multi-disciplinary optimisation of aeroelastically tailored wind turbine blades

Student: Sam Scott

Student: Sam Scott

Supervisors: Alberto Pirrera, Paul Weaver, Peter Greaves (ORE Catapult) and Chong Ng (ORE Catapult)

Wind energy as a source of electricity has become increasingly competitive with other conventional sources, partly due to large increases in wind turbine size and technological advances in design and manufacturing. It has been well established that the individual facets of wind turbine design can no longer be considered separately, due to the highly coupled nature of the sub-systems. Thus, the designer is faced with an aero-servo-elastic problem with a potentially vast design space. As a top-level design process, multi-disciplinary optimisation is being employed to efficiently explore these vast design spaces and the inherently complex variable interdependencies.

This work presents a novel optimisation framework with the aim of broadening the traditional design space by including structural couplings (i.e. bend-twist coupling), that have been demonstrated to reduce extreme and fatigue loads. As load reductions are not enough to justify a new technology, the optimisation framework presented herein aims to assess the repercussions for the whole system, including cost of energy. Full functionality of the optimisation framework is not yet available, therefore initial results are presented. The blade parameterisation method is used successfully to represent an existing 7MW wind turbine using minimal design variables. Additionally, results from aerodynamic and structural sub-optimisations are displayed for blades with varying sweep; illustrating the efficacy of the routines.

Stiffness tailoring of composite shells via thermal prestress

Student: Jonathan Stacey

Student: Jonathan Stacey

Supervisors: Mark Schenk, Matt O’Donnell, Just Herder (TU Delft), Werner van de Sande (TU Delft) and Boudewijn Wisse (Laevo BV)

Composite manufacture often involves curing parts at elevated pressures and temperatures. Due to the anisotropic nature of fibre-reinforced laminates, internal stresses can remain after cooling. These pre-stresses (and resulting warping) are often deliberately avoided, although utilising them can allow tailoring of the structure’s mechanical behaviour. This is especially true for thin shells, and can enable fabrication of tailored composite compliant mechanisms. One example application is a passive exoskeleton (like those developed by Laevo BV), where bending support could be provided by tailored composite shells that still grant the user twisting freedom.

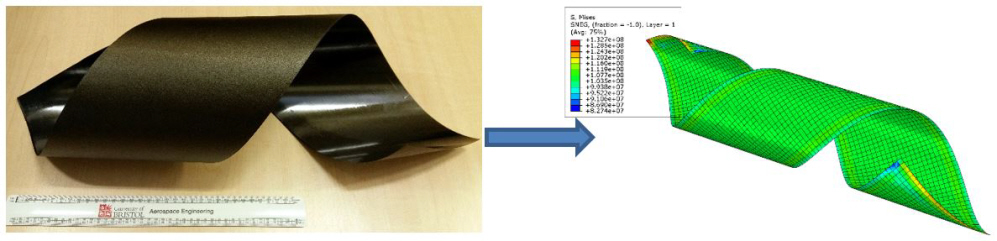

Working in collaboration with Laevo BV and researchers from TU Delft, this project investigated the possibility of applying thermal prestress to reduce the torsional stiffness of cross-ply tape springs (i.e. those that would exhibit maximum warp). New extensions of analytical tape spring models with composite thermal analysis were presented, showing thermal effects causing significant changes to ultra-thin composite shell behaviour. Finite element simulations and experimental investigations of manufactured tape springs were also presented as validation.

Figure 1: Manufactured tape springs were used to validate analytical and finite element geometry predictions.

Modelled zero-twist curvatures matched well with manufactured samples, however not all buckling mode shapes observed in samples could be predicted and twist angles were over-predicted by the analytical model. It was found that there was limited feasibility for zero torsional stiffness tape springs, as well as wider challenges when using thermal prestress such as temperature control, time-dependent properties, and experimental measurement.

Understanding the in-plane behaviour of prepreg tapes: improving the part quality and deposition rate of automated manufacturing

Student: Yi Wang

Student: Yi Wang

Supervisors: Dmitry Ivanov, Stephen Hallett, Jonathan Belnoue, BC Eric Kim and James Kratz

The automated fibre placement (AFP) technique has become one of the mainstream techniques for the manufacturing of composite parts in commercial aerospace. Amongst other advantages, the technique allows to reduce waste and creates a larger design space of structures through tow steering. It is however limited by the occurrence, during the process, of defects (e.g. wrinkles and tow pull off) which are closely related to the in- and out of plane properties of prepreg. In this project, the in-plane shear behaviour of thermoset prepreg was characterised by a unidirectional off-axis tensile test. Different testing speeds and tow widths, consistent with those used in automated deposition processes, were considered. Three different specimen thicknesses were tested. The results indicate that the in-plane shear behaviour of uncured thermoset prepreg is nonlinear and does not vary much with the change of thickness. The influence of testing (layup) speed and tow width were analysed and discussed. It was shown that test rates influence the shear properties of the material considerably. The effect of tow width was however not obvious.

The automated fibre placement (AFP) technique has become one of the mainstream techniques for the manufacturing of composite parts in commercial aerospace. Amongst other advantages, the technique allows to reduce waste and creates a larger design space of structures through tow steering. It is however limited by the occurrence, during the process, of defects (e.g. wrinkles and tow pull off) which are closely related to the in- and out of plane properties of prepreg. In this project, the in-plane shear behaviour of thermoset prepreg was characterised by a unidirectional off-axis tensile test. Different testing speeds and tow widths, consistent with those used in automated deposition processes, were considered. Three different specimen thicknesses were tested. The results indicate that the in-plane shear behaviour of uncured thermoset prepreg is nonlinear and does not vary much with the change of thickness. The influence of testing (layup) speed and tow width were analysed and discussed. It was shown that test rates influence the shear properties of the material considerably. The effect of tow width was however not obvious.

Figure 1 (right): In-plane shear behaviour characterisation of uncured prepreg; (a) Schematic of off-axis tensile test (b) DIC analysis results-shear strain field.