PhD projects: 2023 cohort

Use the links below to jump to research project abstracts

- Microporous hybrid composites for hydrogen storage devices in aerospace and automotive applications

- Enhancing damage tolerance in carbon/epoxy composites via short-fiber reinforcement

- Fracture toughness and impact damage resistance of sustainable composites

- Cellulose and polymer-based composite water filtration media

- Fused Filament Fabrication (FFF) of novel material forms for sustainable high-quality composite structures

- Developing computational models to predict remnant lifetime in composites for space applications

- Exploring novel high temperature matrix resin composites for advanced engineering applications

- Natural fiber-reinforced composites embedded with optical sensors for next-generation sustainable pedestrian footbridges

- Integrally cooled WrapToR truss structures with hierarchical vascular networks

- Investigating thermal and mechanical properties of CFRP composites for hydrogen storage applications

- Micro-scale modelling of thermo-mechanical and environmental degradation of non-oxide Ceramic Matrix Composites (CMC)

Microporous hybrid composites for hydrogen storage devices in aerospace and automotive applications

Student: Aya Abdo

Student: Aya Abdo

Supervisors: Sanjit Nayak, Charl Faul, Ian Hamerton, Valeska Ting

Hydrogen is one of the most promising alternative energy vectors that can potentially replace fossil fuels primarily to meet the UK net zero target by 2050. To facilitate the move towards hydrogen economy there is an urgent need for the development of an efficient storage system for this ultralight gas. Among a number of adsorbent materials tested recently, microporous metal-organic frameworks (MOFs) have shown exceptional hydrogen uptake capacity. However, their granular form and relatively poor stability is a barrier to integrate them into practical storage applications. Integrating these materials into porous hybrid polymer composites will enhance processability, and can potentially provide a solution for high-density hydrogen storage systems. There is very little study conducted on composites of highly porous MOFs with a focus on the suitability of the materials in working conditions. This aim of this project is to address this knowledge-gap and to integrate ultra-porous MOFs and polymers in hybrid composites with a focus on studying their properties in working conditions. The main objective of this project is to develop and study composites of high-surface-area MOFs and microporous/mesoporous polymers with enhanced mechanical and thermal properties for the hydrogen storage applications in automotive and aerospace applications.

Enhancing damage tolerance in carbon/epoxy composites via short-fiber reinforcement

Student: Cameron Abercromby

Student: Cameron Abercromby

Supervisors: Iryna Tretiak, Michael O’Leary, Michael Wisnom

Short Fibre Reinforced Polymer Composites (SFRPCs) are gaining significant interest within industry due to their remarkable properties. Continuous Fibre Reinforced Composites (CFRCs) with high specific stiffness and strength are increasingly applied in automotive and aerospace applications. The adoption of composite materials is increasing as the desire to reduce component mass for environmental and economic reasons. On the other hand, the manufacture of complex components with CFRCs is hampered due to wrinkles or other defects due to the continuous reinforcement preventing in-plane deformation during layup [1]. Meanwhile, the discontinuous nature of SFRPCs allow greater conformability to complex curvatures and stamp forming processes, leading to potential applications in high rate of manufacture applications.

Short fibres also permit the use of recycled reinforcement. Not only does this provide a potential improvement in sustainability, it opens the door to a less expensive feedstock material during a time where carbon fibre demand outstrips supply [2]. With the EU waste directives restricting the quantity of composite waste allowed to go to landfill [3], an effective reuse path is essential.

While CFRCs excel in strength and stiffness, SFRPCs can offer a distinct advantage in notch insensitivity and resilience to stress concentration [4, 5]. The discontinuous nature allow s greater energy dissipation through interactions between fibre and matrix based damage [6], potentially leading to improvements in toughness and damage tolerance. However, the manufacture of discontinuous material demonstrates significant challenges. Discontinuous material size and distribution methods can lead to defects and variability in in-plane strength.

The overarching objective of this research to enable the use of SFRPCs within high performance structures through improvements in manufacture and subsequently explore micromechanical damage mitigation mechanisms present in SFRPCs.

The first objective is to investigate and implement potential manufacturing processes to improve the consistency and uniformity of the discontinuous material and produce parts with minimal defects. A further manufacturing aim is to create a discontinuous reinforcement that can be handled and manipulated similar to conventional dry reinforcement. To satisfy these objectives bindered discontinuous carbon fibre preforms will be manufactured.

The effect of material parameters such as fibre length and dispersion techniques have on defects and internal mesostructured will be investigated. The aspect ratio and the thickness of the chopped carbon fibre platelets will be varied with the effect on the preforming distribution and resulting mechanical performance analysed.

The potential fracture toughness and damage tolerance effects will be compared against continuous fibre composites. This will also combine high resolution image based strain detection with thermography and X-ray Computerised Tomography. This is to provide greater insight into the progressive failure seen within discontinuous reinforcement and where it could be best applied in the future.

- M. H. Hassan, A. Othman, S. Kamaruddin, The International Journal of Advanced Manufacturing Technology 91 (2017) 4081–4094

- J. Zhang, V. S. Chevali, H. Wang, C.-H. Wang, Composites Part B: Engineering 193 (2020) 108053.

- Directive 2008/98/ec of the European parliament and of the council of 19 November 2008 on waste and repealing certain directives.

- D. E. Sommer, S. G. Kravchenko, W. B. Avery, R. B. Pipes, Composites Part A: Applied Science and Manufacturing 162 (2022) 107133.

- C. Qian, L. Harper, T. Turner, N. Warrior, Composites Part A: Applied Science and Manufacturing 42 (2011) 293–302.

- S. G. Kravchenko, C. Volle, O. G. Kravchenko, Composites Part A: Applied Science and Manufacturing 149 (2021) 106524.

Fracture toughness and impact damage resistance of sustainable composites

Student: Boss Budninpech

Student: Boss Budninpech

Supervisors: Karthik Ram Ramakrishnan and Stephen Hallett

The increasing demand for sustainable composites stems from the critical need to mitigate environmental impacts and ensure a more sustainable future. Traditional fibre-reinforced composites, such as carbon/epoxy and glass/epoxy systems, exhibit excellent strength and stiffness but are associated with energy-intensive manufacturing processes and complex recycling and energy recovery methods, which result in low efficiency and raise significant environmental concerns. Sustainable composites, including bio-based materials derived from renewable sources and recyclable systems employing thermoplastic and vitrimer matrices, present environmentally favourable alternatives. These materials are integral to achieving net-zero carbon objectives and addressing the ecological challenges posed by conventional composites. However, the adoption of these sustainable composites in structural applications requires a thorough understanding of their mechanical behaviour, particularly their damage resistance under impact loading. For non-penetrative impacts, damage is predominantly characterized by interlaminar fracture, specifically delamination, which compromises structural integrity by reducing strength and stiffness, potentially leading to catastrophic failure. Enhancing interlaminar fracture toughness, especially in Mode II (shear mode), is critical for extending the operational durability of sustainable composites under low- and high-velocity impacts. This enhancement is essential to position these materials as viable substitutes for traditional composites in demanding applications, such as marine and automotive industries.

This research focuses on evaluating the Mode II interlaminar fracture toughness of sustainable composites, emphasizing strain rate effects through end-notched flexure (ENF) testing under both quasistatic and high strain rate conditions. A detailed fractographic analysis of fracture surfaces will be conducted to elucidate the failure mechanisms, complemented by the development and evaluation of a toughening strategy to improve fracture toughness. The results will be integrated into a finite element model to predict delamination behaviour under impact loading and assess its impact on the structural performance of sustainable composites.

Cellulose and polymer-based composite water filtration media

Student: Mary Sintim Donkor

Student: Mary Sintim Donkor

Supervisors: Steve Eichhorn, Charl Faul, Sanjit Nayak

Water is the most important resource to sustain life emphasizing its relevance in most human activities. Nevertheless, urbanisation, overpopulation, industrial activities, human activities, landfill expansion, mining activities, and urban wastewater continue to pollute water bodies. It is estimated that over 2.1 billion people globally do not have access to safe and clean drinking water with 3.4 million people dying each year from consuming contaminated water [1].

Water bodies are contaminated with organic and inorganic pollutants, oil, microbes, micro and nano plastics, pathogens, pesticides and pharmaceutical wastes [2]. The presence of all these pollutants is detrimental to aquatic ecosystems, humans and the environment due to their bio-accumulation and toxicity.

In most developing countries, such as in Africa, illegal mining activities are a challenging problem affecting potable water availability. The water bodies are contaminated with arsenic, mercury, cadmium and other toxic substances released during mining activity. Besides mining, plastic waste, agrochemicals from agricultural activities and untreated domestic sewage pollute the water resources [3].

The wide impact of water pollution has created an urgent need for water purification approaches to decontaminate industrial and household wastewater before discharging it into rivers and other waterways. In water treatment, membrane separation processes have emerged as a promising solution because of their effectiveness, selectivity, and potential to safeguard water resources. The membrane fabrication process, with techniques such as electrospinning, phase inversion, and wet spinning is being explored for pollutant separation applications. Among these, electrospinning has gained significant interest due to its ability to produce membranes with a high surface area to volume ratio, fine pore sizes, lightweight, a wide variety of fibre composition and tuning of fibre sizes, and flexibility to spin biodegradable polymers.

Wastewater treatment materials must be sustainable (i.e. lower carbon footprint and environmentally friendly), low cost and with superior performance. Cellulose, abundant in nature, has been extensively studied for this purpose. Cellulose derivatives are spun into water filtration to decontaminate oil-polluted water and remove micro and nano plastics. Additionally, porous materials such as zeolites, metal-organic frameworks, activated carbon, and biochar have been researched for removing specific wastewater pollutants.

The presence of multiple contaminants makes decontamination of wastewater challenging. A unique combination of several porous materials producing mixed fractionation within one construct of a water filtration device would be a new approach to multiple contaminants extraction. This project aims to produce a hierarchically structured composite filtration medium for the extraction of multi-component pollutants and prove the efficacy of filtration of mixed polluted aqueous media. To achieve this aim, the initial study will be on electrospinning a fibrous network by incorporating metal-organic frameworks (MOFs), cellulose nanocrystals (CNCs) and zeolites in a polymer and functionalize the surface. The next step will be to explore electrospinning hybrid microporous polymer composites of functionalised MOFs or conjugated microporous polymers (CMPs). The final study will be on incorporating modified hybrid electrospun fibres in foams to develop a foam filter.

The development of these lightweight cellulose-polymer filters can be deployed in low-income countries and disaster-stricken areas for generating portable drinking water. In addition, these composite filters can be tailored for the removal of heavy metals, dyes or organic pollutants which would be helpful for industrial waste treatment. Also, the filtration system will work in a gravity-fed or low-pressure system reducing the energy cost associated with the use of a high-pressure filtration system.

References:

[1] “Mission | WHOlives.” Accessed: Sep. 30, 2024. [Online]. Available: https://wholives.org/our-mission/mission/

[2] A. A. Nayl et al., “Review of the Recent Advances in Electrospun Nanofibers Applications in Water Purification,” Polymers (Basel), vol. 14, no. 8, Apr. 2022, doi: 10.3390/POLYM14081594.

[3] “Water Pollution in Africa: What are the Key Causes?” Accessed: Sep. 30, 2024. [Online]. Available: https://aquasalveoforlife.com/blog/water-pollution-in-africa-what-are-the-key-causes

Fused Filament Fabrication (FFF) of novel material forms for sustainable high-quality composite structures

Student: Jakub Jakimow

Student: Jakub Jakimow

Supervisors: Dmitry Ivanov, Dominic Palubiski, Ben Woods, Ian Hamerton

This project aims to address the demand for sustainable composite materials in various industries, specifically in reducing the waste associated with their use. Composite structures currently face issues with manufacture defects, poor repairability and recyclability. This leads to large waste, with good quality parts being scrapped due to minor defects. Advancements in recycled carbon material forms such as Discontinuous Aligned Fibre Filament (DcAFF) provide a means to improve the sustainability and performance of the manufacture process of composites.

The project aims to develop a novel bi-matrix system for Fused Filament Fabrication (FFF), consisting of Covalent Adaptive Networks (CANs) and fast-curing resins. The primary objective of the work is to enhance the mechanical properties and printability of composite parts by addressing the limitations in porosity, fibre volume fraction, steering and inter-ply adhesion. Improvements in rheological control of the matrix system aim to make FFF a viable method for manufacture of high performance and sustainable components.

The potential applications of this research cover industries such as aerospace, automotive wind energy where high strength and lightweight materials are key. By developing a more efficient and sustainable manufacture process, the outcome could drastically reduce waste material, and the environmental impact involved in composite use. The use of recycled material forms and improved repairability properties will further contribute to a greater towards more sustainable composite manufacture practises.

The novelty of the research is found in the unique introduction of CANs in the FFF process. CANs possess desirable mechanical and chemical properties, with notably, the ability to undergo re-bonding after curing, making them well suited for repairability and recyclable composites. The DcAFF process and the introduction of CANs aims to push the boundaries of current FFF processes by combining sustainable material forms and process control techniques to produce high quality, sustainable composite components.

Developing computational models to predict remnant lifetime in composites for space applications

Student: Lucas Lu

Student: Lucas Lu

Supervisors: Giuliano Allegri, Ian Hamerton, Kate Robson Brown, Rainer Groh

Background

In the low Earth orbit (LEO) environment, advanced composite materials have been considered as innovative alternatives to metal materials because of their desirable high strength-to-weight ratio and excellent thermal properties. However, the LEO environment is a harsh one and exposure to atomic oxygen (AO) is a constant threat to polymeric materials because the highly reactive oxygen atoms react with the polymer’s surface, eroding the materials by forming volatile oxides which are removed from the surface.

The wider application of composite materials in space is limited. The cost of deploying materials in space is high and the ability to predict their lifetime in LEO is limited. Therefore, there is a growing demand to develop computational models that help predict the remnant lifetime of composites in LEO as this is an important step towards understanding currently used materials and developing the next generation of replacements.

Aims

This project aims to develop a series of computational models that predict the remnant lifetime of composite materials that are designed for space applications. Initial work will focus on the use of the Monte Carlo model, which predicts the surface roughness and erosion depth after defined periods of AO exposure. Kapton H samples will initially be used since they have well-known properties and their degradation in LEO is well understood. This study will aid the development of a reliable predictive model that can be used to predict AO erosion for other types of polymer materials.

Initially, the LEO environment will be simulated using a radio-frequency (RF) plasma chamber facility to generate energetic oxygen ions to erode the surfaces of samples. The RF plasma chamber replicates LEO erosion yield well, but is less effective in reproducing the surface effects observed in composites after LEO exposure. Therefore, it will be important to understand the nature of the plasma produced and mass spectrometry will determine the degree of oxygen dissociation and plasma emission spectra.

Atomic force microscopy (AFM) and laser profiling techniques will be used to determine the surface roughness before and after AO exposure, and these data will be used as input data for the Monte Carlo simulation, while the surface roughness after exposure will be compared with simulation results. Spectral analysis (e.g. optical photothermal infrared, OPT-IR, spectroscopy) will be used to ascertain the chemical nature of the species on the surface of the laminates before and after exposure to determine the mechanisms of degradation.

Potential applications:

The Monte Carlo model can predict the effects of AO erosion on materials, potentially reducing the need for costly and time-consuming space flight experiments. In the later stages of the project, the integrated predictive models will be able to predict the sample's mechanical and thermal properties after AO exposure.

The study highlights differences between ground-based plasma asher tests and actual LEO conditions, particularly in surface roughness development. These findings can lead to improvements in ground-based testing methodologies. However, the method is material agnostic and might be applied more widely to other composites in equally demanding exposure environments.

Novel Engineering and Physical Sciences aspects:

With reliable Monte Carlo model development, the physical parameters can be modified to represent other types of polymer materials, expanding its applicability to a broader range of space materials.

Comparison of simulation with experimental results reveals that while a plasma asher can simulate mass loss similar to LEO conditions, it may not accurately replicate surface roughness changes, highlighting a need for improved ground-based testing methods.

The research combines materials science, plasma physics, space engineering, and computational modelling, demonstrating a novel interdisciplinary approach to studying space environment effects on materials.

Exploring novel high temperature matrix resin composites for advanced engineering applications

Student: Tierney McArdle

Student: Tierney McArdle

Supervisors: Ian Hamerton, Bassam Elsaied and Dong Liu (Oxford)

The continuous push for performance retention at high-temperatures and improved strength-to-weight ratios has been a crucial factor in developing novel materials for propulsion materials and wider aerospace applications. Advanced composite materials offer superior toughness and lower specific densities when compared to conventional metal alloys. Additionally, retention of mechanical properties at elevated temperature indicates their potential widespread implementation in aerospace applications. Much research has been conducted to develop thermoset resin systems with enhanced thermal and moisture durability properties. The employment of these advanced composite systems in propulsion components would lead to reductions in both component mass and cooling requirements, consequently lowering fuel consumption and exhaust gas emissions.

There has been specific interest into cyanate esters due to their tuneable viscosity properties for resin infusion and high glass transition temperatures, making them suitable for a range of applications. Previous research has incorporated small amounts of polydimethylsiloxane into cyanate ester networks, to reduce moisture absorption and enhance toughness. Susceptibility to water leading to moisture uptake is a key limitation to the widespread application of advanced composites in aerospace and propulsion applications, so a similar approach of incorporating a siloxane into the resin matrix was adopted. Optimisation of the resin composition aims to achieve a balance between moisture resistance, degree of polymerisation, and network architecture; which are crucial factors for the material's performance and ensuring their use in long-term, oxidising environments. However, poor compatibility between siloxanes and cyanate esters has proven to be a historical challenge, often resulting in significant phase separation during manufacture. Although there is some understanding of the cyanate ester resins of this nature, their behaviour when combined with higher concentrations of silicon-containing species remains unexplored, offering a degree of novelty to this body of research. This investigation aims to evaluate the resin system's suitability for practical high-temperature aerospace applications, bridging the gap between laboratory research and real-world implementation. Novel material systems for high-temperature applications are crucial for advancing modern aerospace technologies. Characterising these materials’ mechanical and thermal behaviour will be essential for understanding their performance in harsh environments.

Natural fiber-reinforced composites embedded with optical sensors for next-generation sustainable pedestrian footbridges

Student: Ronald Mwesigwa

Student: Ronald Mwesigwa

Supervisors: Eleni Toumpanaki, Steve Eichhorn, Neha Chandarana

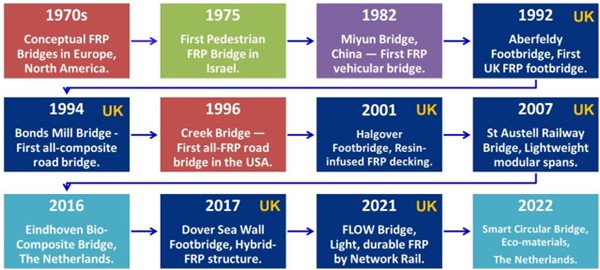

Fiber-reinforced polymer (FRP) composites are gaining popularity over steel and concrete materials in bridge construction due to their lightweight nature, ease of assembly, corrosion resistance, and reduced foundational requirements. Although FRPs are less suitable for vehicle-based bridges due to the high vibrations from traffic, they are widely used in pedestrian footbridges, as shown in Figure 1.

Figure 1: Timeline of FRP composites in bridge construction from the 1970s.

To achieve the 2050 net-zero carbon target, the construction industry is adopting plant-based materials for their carbon retention properties. As a result, FRP composites have advanced to include natural fiber-reinforced polymer (NFRP) composites, which integrate natural fibers for structural strength, and a synthetic or bio-based resin to distribute forces effectively. The structural potential of NFRPs has been displayed in notable projects, such as the Smart Circular Bridge built in Almere, The Netherlands, in 2022. This bridge, constructed with flax fibers embedded with FBG sensors and 24% bio-polyester resin, challenges misconceptions about the durability and moisture sensitivity of NFRPs. Future applications aim to incorporate 60% bio-resin content to enhance strength, resin distribution, and moisture resistance. While these advancements are encouraging, uncertainties about the long-term performance of NFRPs under varying loads and environmental conditions are still a significant concern. One key limitation is their lower fatigue performance compared to synthetic composites, making them less suitable for structures exposed to repeated or dynamic loading. Additionally, the natural fibers in NFRPs exhibit viscoelastic behavior, which increases their susceptibility to creep deformation, leading to dimensional instability over time. Moisture absorption is another significant challenge, as it causes fiber swelling and weakens the bond between fibers and resin, ultimately compromising the strength and durability of NFRPs. Addressing these challenges highlights the need for further research into materials design and development to optimize the performance and reliability of NFRPs.

Embedding optical sensors within natural fiber-reinforced polymers (NFRPs) enables real-time structural health monitoring by continuously measuring critical parameters such as deformation and strain. These sensors provide precise, ongoing data, surpassing the limitations of traditional visual inspections, which can be subjective and require physical access. For footbridge applications, optical sensors offer distinct advantages by measuring strain and temperature continuously along the fiber. This capability allows for the detection of localized damage or strain variations that might otherwise go unnoticed. Such detailed monitoring is particularly valuable for footbridges, which are exposed to environmental factors and dynamic pedestrian loads. By enabling early damage detection, these systems facilitate timely maintenance, enhance user safety, preserve structural integrity, and reduce lifecycle costs. Additionally, given the responsiveness of footbridges to dynamic loads, vibration-based monitoring methods complement optical sensors, further improving reliability and sustainability.

This study aims to design and manufacture sustainable and low-cost NFRP composites with embedded optical sensors for footbridge applications. It will evaluate their manufacturing quality and long-term durability under varying loads and environmental conditions and assess their environmental, economic, and social impacts against traditional materials. Specific objectives are to: (1) design and manufacture NFRP composites using vacuum-assisted resin infusion (VARI) and embedding optical sensors for real-time structural health monitoring in footbridges; (2) evaluate the manufacturing quality of the NFRP composites through imaging and their long-term durability under varying loads and environmental conditions; (3) assess the environmental, economic, and social impact of the NFRP composites in comparison to traditional steel and concrete materials, considering their implications through life cycle sustainability assessments (LCSA).

This study aligns with the United Nations sustainable development goals (SDGs), such as SDG 9 (industry, innovation, and infrastructure), SDG 11 (sustainable cities and communities), and SDG 13 (climate action). It minimizes infrastructure projects' carbon footprint while enhancing urban sustainability and resilience. Through advanced optical sensing technologies, the study enables precise, non-destructive monitoring and cost-efficient maintenance of the pedestrian footbridge. This innovation promotes the shift towards greener and more resilient infrastructure, positioning NFRPs as a sustainable and practical alternative to traditional materials and setting up new standards for future civil engineering advancements.

Integrally cooled WrapToR truss structures with hierarchical vascular networks

Student: Robert Oxford Pope

Student: Robert Oxford Pope

Supervisors: Ben Woods, Laura Pickard, Mark Schenk

High-energy physics experiments rely on high-performance tracking detectors composed of silicon sensors mounted on lightweight structures. These structures must not only provide adequate support but also incorporate a network of cooling fluid for sensor thermal management. The efficiency of the detector significantly influences the quality of experimental results. Current state-of-the-art tracking detectors utilise a network of metallic or plastic pipes containing cooling fluids. Despite the adequate cooling performance of this design, future tracking detectors will require more efficient cooling solutions to enhance their performance. Embedding a vascular cooling network within the composite laminate eliminates the need for foreign materials, enhancing thermal coupling, thermoelastic stability and overall through-thickness radiation length.

This work aims to develop a novel embedded vascular manufacturing method using the vaporisation of sacrificial components. Adequate geometric resolution of the vascular network within the carbon composite is required to support two-phase refrigerant flow, essential for high-energy physics sensor cooling. These embedded vascular networks will be integrated into Wrapped Tow Reinforced (WrapToR) truss structures developed at Bristol, with the network supplied by a hierarchical refrigerant delivery system, analogous to the fluid transport mechanisms of branches and leaves.

Enhanced geometric resolution of the embedded vascular networks coupled with a hierarchical fluid delivery mechanism is an unexplored yet promising area of research for applications with demanding thermal and mass requirements. These include high-energy physics sensor support structures, spacecraft primary structures and carbon composite battery casings. To achieve these aims, the following objectives are summarised as follows:

- Develop a robust and repeatable vascular fabrication technique with enhanced geometric resolution and capable of integration into a hierarchical fluid delivery system.

- Investigate the thermal and mechanical properties of a composite cold plate with an embedded pressurised refrigerant.

- Assess the long-term performance of a carbon composite under exposure to a two-phase refrigerant.

Investigating thermal and mechanical properties of CFRP composites for hydrogen storage applications

Student: Jula Schroeder

Student: Jula Schroeder

Supervisors: Ian Hamerton, Fabrizio Scarpa, Sebastien Rochat, Jonathan Meegan (Syensqo), Patrick Fairclough (Sheffield)

Hydrogen fuel is gaining recognition as a key solution for achieving net-zero emissions by 2050. Hydrogen storage presents significant challenges due to its low volumetric energy density, requiring storage solutions that often involve high pressure and low temperatures. Currently, the space and energy industries use metallic tanks (Type I) for storing liquid hydrogen fuels because metals offer uniform expansion and contraction properties. However, these tanks are heavier, less gravimetrically efficient, and more brittle. A major focus has been the development of carbon fibre-reinforced plastic (CFRP) composites for hydrogen storage tanks due to their high strength and lightweight characteristics. However, challenges persist, particularly concerning the vulnerability of the fibre-matrix interface and the inevitable microcracking that occurs due to repeated refuelling cycles under the cryogenic condition with liquid hydrogen (- 253 °C). At the microscale, the formation of microcracks transversely across laminates can lead to the failure of the fibre-matrix interface as a result of poor interfacial shear strength (IFSS). As the load increases, these microcracks can grow, causing hydrogen leakage, which can have catastrophic consequences.

The fibre-matrix interface plays a vital role in composites failure. Strong interactions between fibres and the matrix are crucial for enhancing a composite's overall properties, with effective load transfer relying on strong interfacial adhesion. Recent research has revealed that this interface (more appropriately termed an interphase region) has a multiphase structure with distinct properties influenced by factors such as surface tension, electrostatic forces, chemical bonding, and mechanical adhesion. However, to date, the literature has focused on the supra-ambient performance of CFRP composites.

It is evident that some fibre/matrix combinations offer better performance at cryogenic temperatures (as evidenced by developing a higher IFSS, fewer microcracks, and greater longevity during extended thermal cycling), but the reasons for this and the factors that contribute most to the performance remain unclear. While experimental techniques to characterise the fibre-matrix interphase have improved significantly in recent years, directly investigating the molecular structure and response of this interphase region - especially at cryogenic temperatures - remains a challenge. In this context, molecular dynamics (MD) simulations can complement experimental efforts by providing valuable guidance for designing new, chemically functionalised fibre-matrix interphases optimised for cryogenic environments in CFRP composites.

The project’s main focus is understanding the changes and failure of the fibre-matrix interface in CFRP composites for hydrogen storage applications. Key objectives of this project include:

- Manufacture CFRP composites with various matrices and fibre systems through different processes.

- Investigate the thermal characteristics of CFRP composites at cryogenic temperatures.

- Design and conduct rigorous testing to characterise the composite materials' performance for hydrogen storage applications, such as fatigue testing, cryogenic cycling, and hydrogen permeability.

- Apply molecular modelling to gain a deeper understanding of the system's conformational behaviour and associated physico-mechanical properties at cryogenic temperatures.

This research offers significant potential for enhancing sustainability in the transportation sector by utilising CFRP hydrogen storage tanks. The approach combines MD simulations with advanced experimental techniques to improve understanding of the fibre-matrix interphase, supporting the development of lighter, stronger, and more durable materials for cryogenic applications.

This project is supported by Syensqo and is carried out in collaboration with the University of Sheffield.

Micro-scale modelling of thermo-mechanical and environmental degradation of non-oxide Ceramic Matrix Composites (CMC)

Student: Cyril Varghese Thankachen

Student: Cyril Varghese Thankachen

Supervisors: Luiz Kawashita, Vasav Dubey, Giuliano Allegri, Bassam Elsaied

This project focuses on understanding how non-oxide ceramic matrix composites (CMC) perform under extreme environmental conditions, particularly silicon carbide (SiC) fibres with boron nitride (BN) interphases embedded in SiC matrices. Such materials can not only operate continuously at high temperatures (up to 1400 ◦C) without the need for active cooling, but also are considerably lighter than their metallic counterparts and, as such, are increasingly replacing nickel superalloys in hot sections of gas turbines and aero-engines.

This research aims to investigate the microscale degradation mechanisms of CMCs when subjected to thermo-mechanical loading coupled with environmental oxidation. Microscale Finite Element (FE) models accounting for thermo-mechanical degradation as well as oxidation reactions will be developed to replace current empirical and semi-analytical analysis tools which are currently the state-of-the art in industries such as aerospace and power generation. These will then be verified and validated against experimental data on single tows (i.e. ‘minicomposites’) before being applied to meso-scale models of the 2D and/or 3D woven CMC laminates used in the manufacture of real components.

The potential impact of this research is significant. By improving the understanding of the thermo-mechanical and oxidative behaviour of the various phases within the material, this work will contribute to the development of safer, more efficient, and more durable components for a variety of high-temperature applications. Replacement of metals with CMCs in aero-engines can reduce weight and improve fuel efficiency, contributing to lower emissions and reduced operating costs. Beyond aerospace, this work will provide a step-change in the ability to design CMC components for various industries, including nuclear fission/fusion and gas turbines for power generation.

This project bridges various aspects of physical sciences and engineering by combining knowledge of thermo-mechanical and oxidative behaviour of advanced CMCs with the design and manufacture of components for high-temperature applications, with potential for great technological advancements in key sectors such as aerospace and power generation.