Building on wider work funded by the Engineering and Physical Sciences Research Council (EPSRC), Airbus and GKN, Groh’s research is the first to identify the contribution of both thickness and material property variation on structural performance, and therefore on weight and cost savings. The paper, entitled ‘Buckling analysis of variable angle tow, variable thickness panels with transverse shear effects’, has since been published in Composite Structures.

The development of composite materials and structures has gained significant momentum in recent years as diverse industrial applications drive performance to ever higher levels and also reduce both structural weight and costs. Products such as new aircraft (eg Airbus A350 and Boeing 787), automobiles (eg BMW i3), wind turbines and a wide range of sporting goods continue to hit the marketplace. On top of these developments, Variable Angle Tow (VAT) composites offer outstanding opportunities for reducing the weight of aircraft structures further by offering the possibility of tailoring material properties and geometrical features in one go.

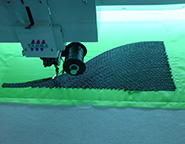

Currently, high-performance carbon-fibre composites are manufactured by building up a stack of individual layers with straight, unidirectional carbon fibres held together by a matrix material. The research paper investigates the use of advanced laminated carbon-fibre composites that feature varying fibre orientations within each layer known as Variable Angle Tow (VAT) composites. Compared with their straight-fibre counterparts, VAT composites hold great promise in improving the load-carrying capabilities of thin-walled structures in aircraft wing skins and improving stress concentrations around holes. In this manner, the technology holds great promise in reducing aircraft weight, fuel consumption and costs.

ICCS17, which was held in Porto this year and featured 700 presentations, is the leading conference in the world devoted to composite structures. Groh, whose award came with a cash prize of 1,000 euros, said: ‘On a personal note I feel honoured to receive this award and want to acknowledge the encouragement and support of my colleagues. I am delighted that the significance of our work has been recognised at this level.’

The research team, led by Professor Paul Weaver from the University’s Department of Aerospace Engineering and ACCIS research group, consists of three PhD students and three post-doctoral researchers and has made a series of landmark contributions to the technology over the past five years in both structural design and development of new manufacturing processes.

Professor Weaver said: 'Rainer’s work is particularly exciting as it really pushes the potential of structural composite materials to their very limits.’